Inteva’s InLite™ product offerings provide mass saving technologies that are both economical and sustainable. Our unique one-step approach to Natural Fiber Reinforced Polypropylene (NFPP) combines multiple manufacturing steps into a single tool, resulting in a product that is 40 percent lighter than the comparable injection molded part. Whether Hard Clad or Soft Clad, Inteva’s one-step solution provides the most economical approach to NFPP available on the market today.

Hard Clad Nonwoven One-Step

One-step, Class A grained and formed lightweight substrate technology for interior trim panel applications as a low-mass option to hard injection molding.

Soft Clad Nonwoven One-Step

This one-step approach combines forming, back injecting, cladding and in-mold trimming of a nonwoven material into a single tool.

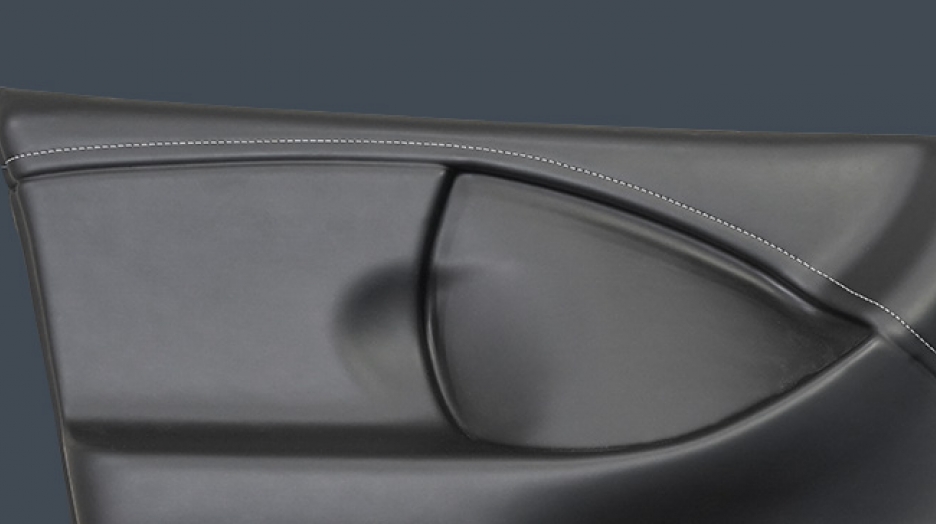

Injection Mold behind Inteather™ Thin Film

A process that uses special tooling to injection mold a rigid substrate material behind our Inteather™ Thin Film for improved surface quality, haptics and gloss.

Sustainability

We are making efforts to recover unused NFPP offal that is typically landfilled and regrind / re-pelletize that waste into usable material which can be put back into the manufacturing process.

Learn more about InLite

Interested in learning more about what InLite offers and how it could help your next program? Fill out the contact form below to receive a detailed informational kit, or email Tom Sybrandy at tsybrandy@intevaproducts.com with questions.